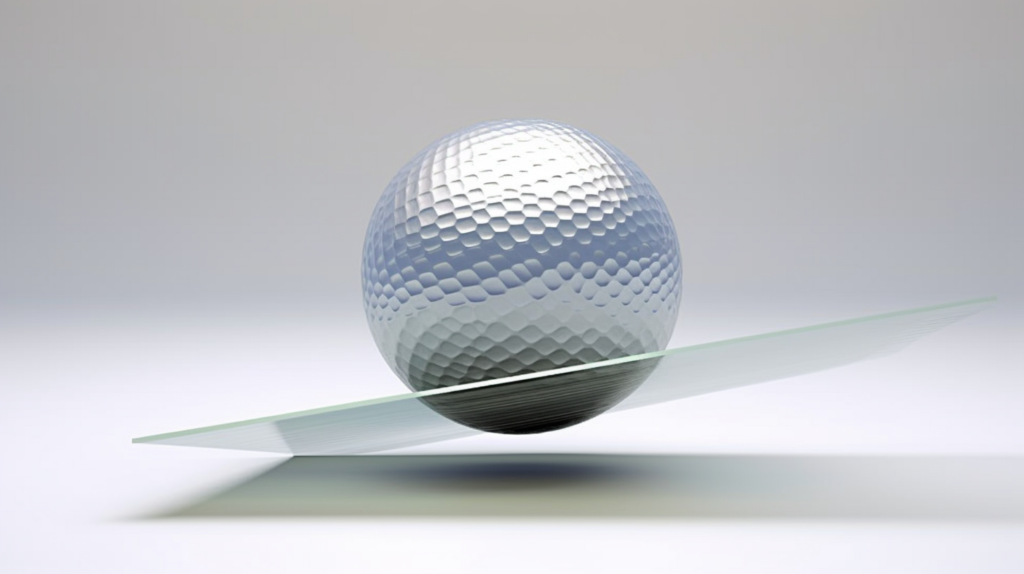

Have you ever wondered why golf balls are covered in what look like little craters? Those surface divots are actually called “dimples”, and they serve an important aerodynamic purpose.

The dimpled exterior of a golf ball helps it fly farther than a smooth one by reducing aerodynamic drag during flight.

Let’s dive in to understand the purpose dimples serve and how they achieve better flight performance through some clever physics.

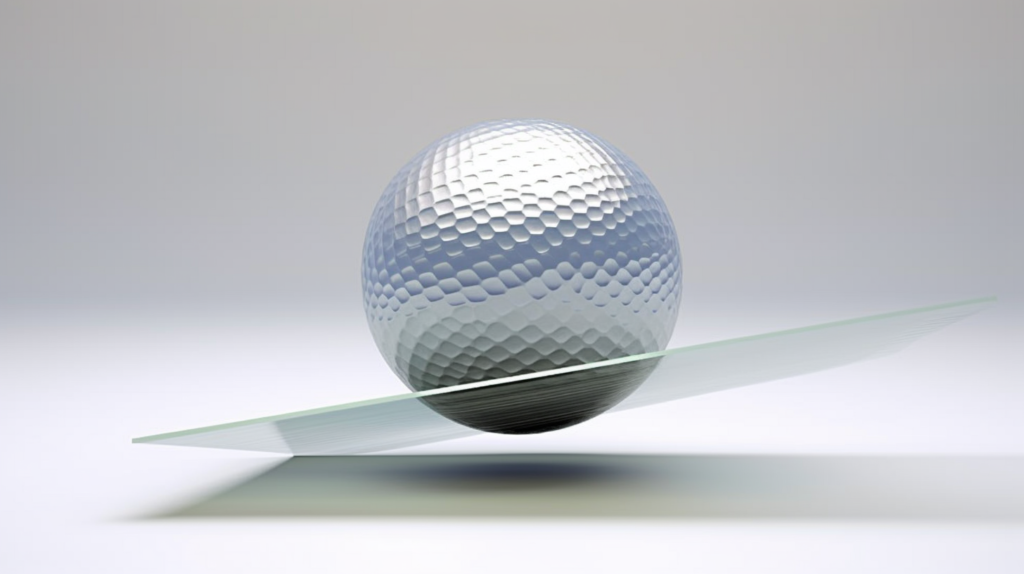

Aerodynamics Of A Smooth Ball

A golf ball that has a perfectly smooth surface can initially travel pretty well through the air when struck, however it soon loses speed and distance due to the aerodynamics acting on it.

As the smooth ball with no surface indentations flies through the air, the airflow around it becomes turbulent. The smooth and slippery surface of the ball causes the boundary layer of air closest to the ball to separate early along the back side.

This leads to an abrupt transition to turbulent airflow in the wake behind the ball. The early transition to this turbulent wake drastically increases pressure drag on the ball, slowing it down rapidly.

The smooth surface provides no means of tripping or energizing the boundary layer in order to delay the airflow separation.

The end result is that while a smooth ball has less skin friction drag initially due to its perfectly smooth surface, it experiences a lot more pressure drag overall from the turbulent wake.

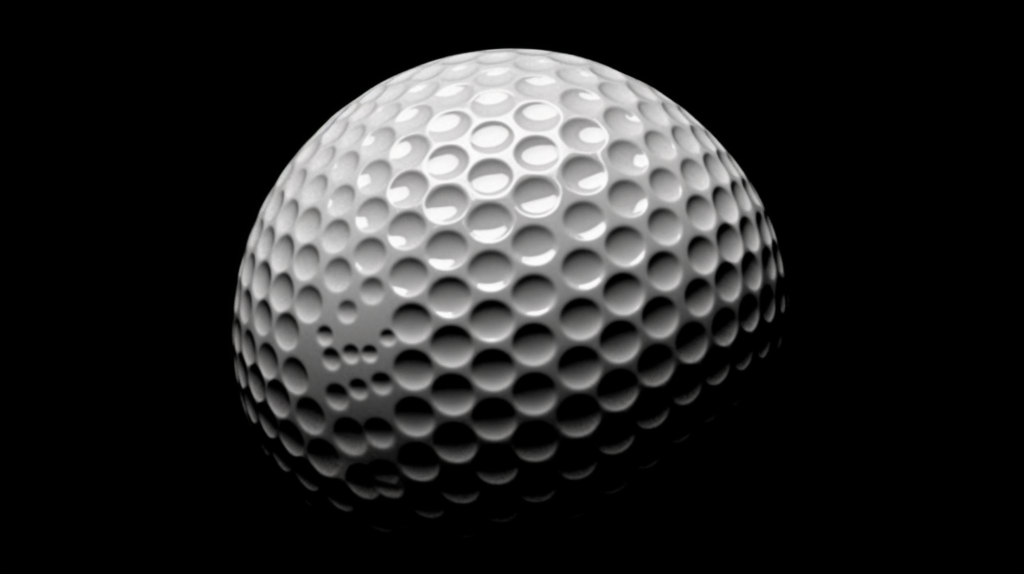

Purpose Of Dimples On A Golf Ball

The purpose of adding surface dimples or indentations to a golf ball is to help trip and energize the boundary layer so that it stays attached longer along the back side of the ball before separating.

This delays the transition to a turbulent wake so that pressure drag is substantially reduced, enabling the golf ball to fly much farther. The dimples trigger a thin turbulent boundary layer right along the ball’s surface.

This thin turbulent layer is able to remain smoothly attached beyond the dimple crests along the aft side rather than abruptly separating like on a smooth ball. The end result is that the trailing airflow over the dimpled portions remains laminar or smooth for a longer duration.

This allows the dimpled golf ball to experience less overall air drag than a smooth golf ball, enabling it to fly significantly farther.

How Dimples Reduce Drag

The main way that having dimples on the surface reduces aerodynamic drag on a golf ball is by keeping the boundary layer attached for longer.

As covered earlier, when the boundary layer abruptly detaches from the surface on the aft portion it leads to a low pressure turbulent wake that drastically increases pressure drag – slowing the ball down.

The dimples energize and trip this boundary layer as it passes over them, allowing it to cling to surface longer before separating.

In addition, the curved contours of the dimples helps trap vortices of airflow within each dimpled pocket on the surface. This helps to energize the overall flow field around the ball through vortex shedding and interaction between neighbouring vortices.

This maintains smooth attached airflow longer over the aft portion. These vortices add energy to the flow which help the ball push through the air easier, reducing pressure drag even more allowing it to fly farther.

So in summary, the dimpled surface keeps the boundary layer attached longer through flow trip and vortex trapping while providing an energized flow field that reduces turbulence in the balls wake – all helping substantially reduce aerodynamic pressure drag compared to a smooth ball.

Optimizing Depth, Size And Pattern

There is a delicate balance when optimizing the depth, size and pattern layout of dimples on a golf ball. The dimples need to be the right depth to generate low drag vortex flow without making them too deep which adds unnecessary drag.

Their size and distribution density plays a role in allowing smooth passage of airflow from one dimple to the next. And finally, the pattern used affects how evenly lift and drag characteristics are balanced.

If dimples are too shallow, the indentations are not enough to adequately trap the vortices generated and energize flow. If dimples are excessively deep, the sharp contours induce too much drag reducing the potential efficiency gains.

When it comes to size, small tightly packed dimples don’t channel airflow efficiently from one indentation to the next. Conversely, overly large dimples reduce the effective surface area needed to trip the boundary layer.

The layout pattern aims to provide as uniform speading of dimples across the entire ball surface as possible. This ensures low pressure drag vortices are evenly distributed in all directions.

The pattern design along with the number of dimples ultimately helps balance the lifting forces with the reduction in pressure drag for optimal aerodynamic efficiency. Golf ball manufacturers invest tons of R&D into optimizing all these interconnected parameters.

Aerodynamics Of A Smooth Ball

A golf ball that has a perfectly smooth surface without any flaws or indentations can fly fairly well initially when struck purely based on its spherical shape.

However, it rapidly loses velocity and distance due to the unfavorable aerodynamics caused by its slippery smooth surface as it flies through the air.

Without any surface irregularities for the boundary layer of air flowing over the ball to trip over, it simply separates very early along the aft portion of the ball.

This leads to the wake immediately behind the smooth ball becoming turbulent very quickly. This early transition to a turbulent and chaotic wake drastically increases pressure drag forces that retard the ball’s velocity.

So while the smooth surface produces low skin friction drag at first, it suffers from high form drag due to the large low pressure wake.

The smooth surface provides no mechanism to energize the boundary layer in order to keep it attached longer on the aft side to reduce turbulence in the balls wake.

Purpose Of Dimples On A Golf Ball

Golf ball manufacturers add literally hundreds of small dimples or surface indentations to golf balls for the purpose of reducing aerodynamic drag during flight. The dimples trigger a thin turbulent boundary layer of air that clings to the outer surface rather than separating too early.

This allows the overall airflow trailing the ball to remain smooth and attached longer than on a smooth ball.

The objective of the dimpled surface is keeping laminar attached airflow along the aft portion of the ball for as long as possible after passing over the dimple indentations across the front and sides.

This delays the separation to turbulence in the ball’s wake compared to a smooth surface.

The resulting smooth laminar airflow over the dimpled surfaces creates less pressure drag allowing the golf ball to fly significantly farther due to the reduction in aerodynamic forces slowing it down.

How Dimples Reduce Drag

Dimples strategically placed across the surface of a golf ball reduce aerodynamic drag in a couple key ways. The indented contours trip the boundary layer flow keeping it attached longer than on a smooth ball by effectively restarting it.

This allows air to flow smoothly over the aft portion rather than separating leading to a turbulent wake. Additionally, the curved shape of dimples traps vortices of swirling air within them as the ball flies.

This natural vortex generation as air flows over the variating surface helps add energy to the overall airflow around the ball.

The trapped vortices along with shedding and interaction of neighboring vortices helps maintain smooth attached airflow longer after passing by the dimples.

These effects allow air to pass over the aft section with less turbulence for lower pressure drag so that less force slows down the ball. This results in the dimpled ball experiencing much less aerodynamic drag compared to a smooth ball during flight.

Optimizing Depth, Size And Pattern

There are several interdependent factors to consider when designing the surface pattern, size and depth of dimples on a golf ball. The depth impacts drag and vortex spinning, the size affects smooth airflow between dimples, and the pattern layout aims to balance lift and drag.

Optimizing these parameters is crucial to maximizing performance.

The depth of the dimples directly impacts the magnitude of vortex rotation within the pockets which affects attached flow. Too shallow and the vortices won’t have enough energy to reduce turbulence.

Too deep and they add unnecessary drag. When it comes to sizing of dimple diameter, overly small tightly packed dimples inhibit smooth passage of air from one indentation to the next.

With overly large dimples the overall surface area covered is reduced limiting boundary layer tripping. Finally the use of a uniform pattern balances asymmetries in lifting forces while providing uniform vortex distribution for drag reduction.

Manufacturers invest tons of R&D dollars into optimizing the combination of dimple depths and diameters for the particular layout pattern used across the ball surface.

Even minute incremental improvements in optimizing these parameters can provide measurable gains in reducing drag for increased distance.

Conclusion

In conclusion, the dimpled surface of a modern golf ball is carefully designed and engineered for aerodynamic performance. The strategic depth, size, and patterning of dimples trip the boundary layer to reduce drag-inducing turbulence in the ball’s wake.

This allows dimpled golf balls to fly significantly farther than smooth ones. Dimple optimization never stops as manufacturers continually strive for even the smallest measurable gains in reducing pressure drag.